Shot Blasters vs. Concrete Floor Grinders – Which Tool is Best For You

There is a wide array of tools in the industry for concrete surface preparation. However, this can make it easy to get overwhelmed with options, or create confusion about the best use for each machine.

That’s why narrowing down machine options by benefits, abilities, and project types is helpful when trying to figure out what you need for your job.

While there’s plenty of concrete preparation machines, from scarifying to sandblasting, and everything in between, two of the most common are shot blasters and concrete diamond grinders. So, let’s go over some of the main differences between the two.

What is a Shot Blaster?

A shot blaster is a machine that shoots fine, abrasive media (generally metal beads) against concrete. This process chips away at the top layer of concrete, exposing a cleaner surface.

You should consider shot blasting if you are going to be working on concrete resurfacing, restoration, and repair projects such as cleaning concrete floors to remove old, thick, stuck-on epoxy coatings or grease stains.

Shot Blasting Advantages

First off, shot blasting is an extraordinarily powerful method of concrete surface preparation.

The velocity of the metal beads striking the concrete allows for a forceful clean that removes even the most stuck-on epoxy coatings, paint layers, or other debris like oil stains.

This makes shot blasting incredibly efficient. Plus, a variety of shot blasting machine sizes allow you to work at the pace that’s best for your job.

Shot blasting’s efficiency advantages go beyond just power and work speed, it’s a self-contained process that requires minimal cleanup.

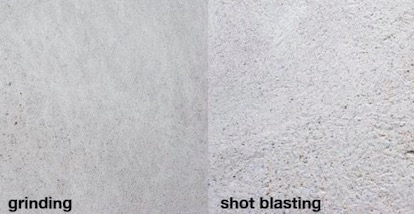

However, it should be noted that shot blasting doesn’t create as smooth or attractive of a surface as diamond grinding. It’s best to utilize shot blasting for projects that require removing heavy coatings, such as in an outdoor parking lot or a warehouse.

Shot blasting machines contain the entire process in a very safe and clean way.

As the metal beads strike the concrete, the broken up debris gets sucked into a dust collector while the metal beads keep flying until they’re pulverized, at which point they join the debris in the dust collector.

All this means that when you are done with your shot blasting project, there will be minimum cleanup required. There won’t be bits of metal and concrete scattered about; you’ll be able to move onto your next process with ease.

What is a Concrete Grinder?

Concrete diamond grinders are machines that spin diamond-tipped discs across concrete, grinding away the top layer and creating an even, textured surface.

Concrete grinding is generally used for creating a non-slip texture on the concrete, or for fixing small irregularities. These machines are great for creating a smooth (yet grippy) texture without deeply chipping away the surface layer of the concrete.

These machines aren’t quite as powerful as shot blasting machines. They won’t work as effectively for removing thick epoxy coatings.

However, this creates an advantage.

Since concrete grinders don’t rough up the concrete as aggressively as shot blasting machines, they’re a great option if your surface needs to look clean and professional.

Concrete grinders are often chosen to prepare concrete flooring for showrooms, high-end garages, or retail spaces for this reason.

It’s important to note that while concrete grinding polishes and cleans the surface you’re working on, it doesn’t make it overly smooth. The diamond-tipped discs create grooves in the concrete that sort of act like treads on a tire.

Concrete diamond grinders are able to fix damage and irregularities like sandpaper does on wood, but ensure the concrete maintains its grip, as needed for applying epoxy coatings or paint.

Advantages of Concrete Grinders

Concrete diamond grinders can be used for a variety of concrete surface preparation projects, and operate well in a wide range of conditions.

Whether you’re working with factory flooring indoors, or preparing a weather-exposed parking garage floor for an epoxy coating, diamond grinders will be of great use.

They’ll work in wet or dry conditions, and can even be a great follow-up process after other surface preparations like shot blasting.

Plus, concrete grinding helps improve the safety of your concrete surfaces in different ways.

Since it helps fix irregularities and damage, it can prevent tripping hazards such as bumps or ridges.

Additionally, the grooves left by the grinding machine create benefits beyond just making coatings and paint easier to apply. They create overall grip, which helps reduce the chances of people slipping and falling, and allows vehicles to come to a stop quicker.

BW Manufacturing’s Multi-Purpose Chassis

As we mentioned, shot blasting and diamond grinding aren’t always the only surface preparation processes you’ll do at a work site.

That’s why BW Manufacturing offers the Multi-Purpose Chassis, which allows you to switch out blast heads, grinding discs, or scarifying attachments with ease.

We are the only manufacturer with an all-in-one interchangeable chassis for concrete surface preparation.

You’ll be shocked at how effortless it is to switch between shot blasting, scarifying, and diamond grinding, saving you time and energy.

You’ll no longer have to wait for additional equipment to be delivered, since you’ll have one machine that can handle it all.

With our Multi-Purpose Chassis, your business will finally have the power to execute tasks with multiple capabilities faster, and with great results.

Project management will become streamlined since you’ll be able to switch between shot blasting, diamond grinding, and scarification operations without bringing in new machines.

Your maintenance and repair costs will also be reduced, now that you’ll only need to maintain a single chassis, rather than multiple machines.

By saving you precious time and money, and improving your performance capabilities, BW Manufacturing’s equipment will empower you to bid for more jobs.

Want to learn more about our Multi-Purpose Chassis? Click the link and see how you could be doing your job better than ever before.

Conclusion

Shot blasting is a powerful, efficient method for concrete surface preparation. It clears away even the toughest of stains, coatings, or paint. It’s great for outdoor parking lots, warehouse flooring, or other environments where power is valued over aesthetics.

It’s a time-efficient, safe, and clean way to prepare your surfaces. However, shot blasting machines cannot be used in wet environments, and don’t have as much of a polishing capability as concrete grinders.

Concrete diamond grinding is a great way to reduce irregularities and prepare surfaces for coatings. It provides a grippy, even surface that looks professional and clean, best for showrooms and high-end garages.

It takes longer to complete than a concrete grinding project, but can be carried out in both wet and dry conditions.

Remember, concrete surface preparation often requires more than one type of process to get the desired results.

BW Manufacturing’s Multi-Purpose Chassis will allow you to switch between concrete diamond grinding, shot blasting, and scarifying processes with ease. You’ll save time and money, and will avoid lots of potential headaches on the jobsite.

Have questions about BW Manufacturing’s shot blasting and concrete grinding machines, or want to learn more about our Multi-Purpose Chassis? Contact us and speak with an expert today!

Back To Blog